It is typically used in gas tanks boat hulls and other items that will be exposed to chemicals or water for extended periods of time.

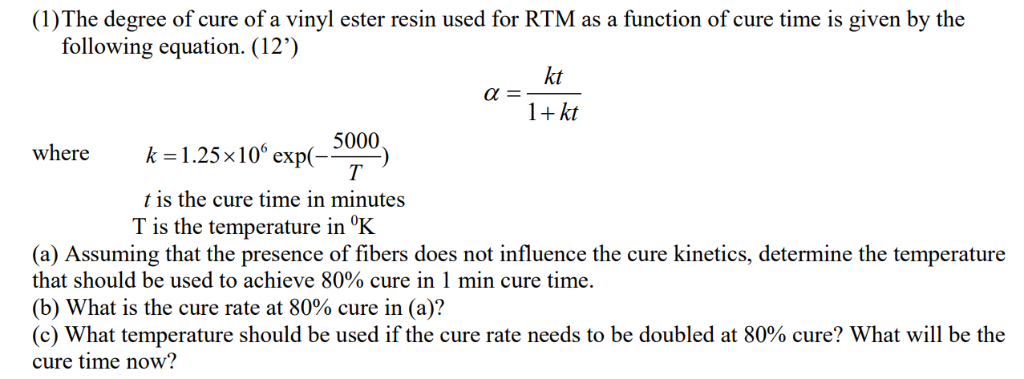

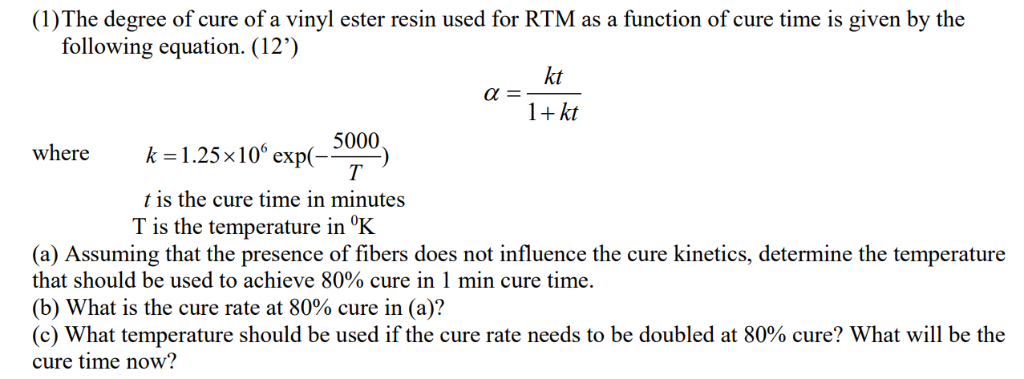

Vinyl ester resin cure time.

Vinyl ester resin is also more resistant to solvents and water degradation.

The degree of crosslinking of a cured up resin depends on the curing system organic peroxide accelerator the curing time the curing temperature and if required the post curing conditions.

Vinyl ester resins are often considered a cross between polyester resins and epoxy resins.

18 to 24 hours.

Ve resin is a tougher resin because of its longer molecular chains.

3 curing unsaturated polyester and vinylester resins with organic peroxides accelerators and other.

This is oversimplified but it does help convey the qualities of the resin.

Advances in fire retardant materials 2008.

West marine has compiled one of the web s most comprehensive collections of technical boating information articles.

It can withstand repeated bending better than both polyester and.

The west advisor articles have answered boaters questions and provided solutions to boating problems for more than 20 years.

About vinyl ester resins.

Vinyl ester resins are the binary resin systems containing a dimethacrylate monomer from which the cured material gains most of its properties and a reactive monomer such as styrene which acts as a reactive diluent and also takes part in the cross linking reaction.